VMC850B CNC Milling inji, a tsaye inji cibiyar

Siffofin Samfur

1.General umarni

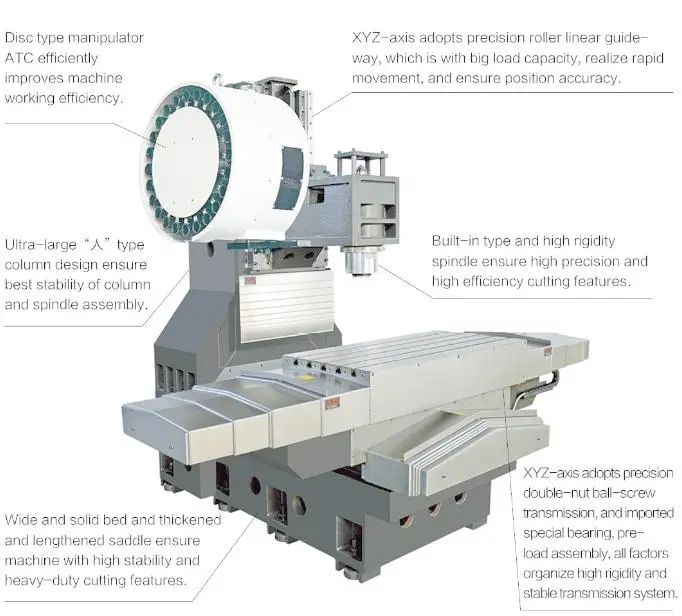

An ƙera wannan injin tare da shimfidar firam na tsaye. An ɗora ginshiƙin akan jikin injin, nunin faifai akwatin sandal akan ginshiƙi yana ƙirƙirar motsin axis Z, faifan sirdi akan jikin injin da ke ƙirƙirar motsin axis Y, Zane-zanen aiki akan sirdi yana ƙirƙirar motsin axis X. Gatari uku duk hanyar jagora ce mai tsayi tare da mafi girman saurin ciyarwa da daidaito mafi girma. Muna amfani da babban simintin simintin gyare-gyaren launin toka don jikin injin, ginshiƙi, sirdi, tebur mai aiki, akwatin sandal tare da fasahar guduro yashi da maganin tsufa sau 2 don kawar da damuwa na ciki na kayan. Waɗannan sassan duk software ɗin SolidWorks ya inganta, wanda ke haɓaka tsauri da kwanciyar hankali ba kawai ga waɗannan sassa ba amma na'ura. Hakanan zai hana nakasawa da girgizar da ke haifar da yanke. Abubuwan da ke da mahimmanci duk ana shigo da su daga sanannun alamar duniya don yin injin tare da kwanciyar hankali mafi girma da karko. Wannan na'ura na iya cimma tsarin niƙa, hakowa, reaming, m, reaming, tapping kuma yawanci ana amfani da su don Soja, hakar ma'adinai, motoci, mold, kayan aiki da sauran masana'antun sarrafa kayan aiki. Ana iya amfani da shi ga kowane irin high daidaici da yawa tsari model. Yana da kyau ga ƙanana da matsakaici, samar da nau'i-nau'i iri-iri, kuma yana iya sanyawa cikin layin samarwa ta atomatik.

2.Three gatura tsarin

Gatari uku duk hanya ce ta madaidaiciya kuma tare da babban ƙira mai tsayi don daidaito mai dorewa. The Motors na 3 gatura suna da alaka kai tsaye tare da high madaidaicin ball dunƙule ba tare da wani rata m hada guda biyu. Kowane ball dunƙule 3 gatura da aka shigo da daga daidai angular tuntube ball dunƙule da kwararrun bearings matches, kuma za mu yi pre-tension ga ball sukurori ga mafi girma daidaito da kuma precision.The Z-axis servo motor yana da atomatik birki aiki. A yanayin rashin wutar lantarki, birki na iya riƙe birki ta atomatik don hana shi juyawa, wanda ke taka rawa wajen kare lafiya.

3.Spindle naúrar

ƙwararrun masana'anta ne ke kera Spindle don tabbatar da daidaito da tsauri. Spindle bearing daga sanannen babban madaidaicin alamar alama ce ta duniya, kuma an taru akan yanayin zazzabi akai-akai kuma babu kura. Bayan haka , duk spindles za su yi gwajin tsauri balance don tabbatar da rayuwa span da kuma aminci.It sanye take da low matsa lamba iska sake zagayowar kariya tsarin, hura low matsa lamba iska a cikin sandar ciki sarari forming iska kariya Layer su hana ƙura, sanyaya cikin. sandal. Don wannan yanayin, igiyar igiya za ta yi aiki a ƙarƙashin wani yanayi mara gurɓatacce, wanda zai kare sashin sandal ɗin kuma tare da tsawon rayuwar spindle. Gudun spindle ba zai iya zama babu wani mataki da aka canza a cikin kewayon saurin sandal, wanda ke sarrafa shi ta hanyar ɓoyayyen ɓoyayyiyar mota don kasancewa tare da aikin jujjuyawar igiya da matsananciyar taɓawa.

4.Tsarin canza kayan aiki

Matsakaicin ƙarfin mujallu na kayan aiki na wannan injin shine 24T kuma an taru a gefen gefen. Lokacin da ya canza kayan aiki, kayan aikin farantin kayan aiki kuma a sanya shi ta hanyar injin motar hobbing cam, bayan sandar ta isa matsayin canjin kayan aiki, ATC zai cimma canjin kayan aiki kuma ya aika aikin kayan aiki. ATC yana ɗaukar injin cam kuma yana yin pre-tension sannan zai iya jujjuya saurin gudu, wanda ya fi dacewa don canza kayan aiki mai sauri da daidai.

5.Coolant tsarin

Injin yana sanye da babban famfo mai sanyaya nutsewa madaidaiciya da babban tankin ruwa. Gudun famfo mai sanyaya shine 2m³/h don tabbatar da isassun sanyaya sake yin fa'ida. Akwai sanyaya bututun ƙarfe a saman ƙarshen akwatin sandal, wanda zai iya yin sanyaya iska da mai sanyaya ruwa don kayan aiki da gudan aiki. An sanye shi da bindigar iska don tsaftace injin da guntuwar aiki.

6.Tsarin huhu

Naúrar huhu na iya tace ƙazanta da damshin da ke cikin tushen iskar gas don gujewa lalacewa da yazawar sassan injin. Solenoid bawul naúrar sarrafa shirin ta PLC don tabbatar da ayyuka na sandar unclamping kayan aiki, spindle cibiyar hurawa, sandal clamping kayan aiki da sandal iska coolant za a iya yi sauri da kuma daidai. Duk lokacin da kayan aikin canza sandar, iska mai matsewa za ta buso daga cibiyar dunƙulewa don tsabtace rami na ciki da kayan aiki don tsayin daka na haɗin gwiwa tare da sandal da kayan aiki. Zai faɗaɗa tsawon rayuwar spindle.

7.Machine kariya

Muna amfani da daidaitaccen garkuwar kariyar tsaro don injin, wanda ba wai kawai zai iya kare fashewar sanyaya ba amma aikin aminci. Kowace hanyar jagora tana sanye da garkuwar kariya don hana sanyaya da yanke yanki zuwa sararin samaniya da rage sawa da zaizayar jagora da dunƙule ƙwallon.

8. Tsarin lubrication

Hanyar jagora da dunƙule ball suna sanye take da tsarin lubrication na tsakiya kuma tare da mai raba mai a cikin Kowane kulli, wanda zai iya samar da mai a ƙayyadaddun ƙayyadaddun ƙima da lokuta don tabbatar da cewa kowace fuska ta zamewa mai mai da ƙananan ƙirƙira. Zai inganta daidaito da tsawon rayuwa na dunƙule ƙwallon da jagora.

9.Chip conveyor tsarin

Muna samar da daidaitaccen na'urar cire guntu ta hannu tare da aiki mai sauƙi. Hakanan zaka iya zaɓar nau'in sikirin na'ura mai ɗaukar hoto ko nau'in hinge.

| Abu | Naúrar | Saukewa: VMC640L | Saukewa: VMC640LH | Saukewa: VMC850L | Saukewa: VMC1000L |

| Kayan aiki | |||||

| Girman kayan aiki | mm | 400×900 | 400×900 | 500×1000 | 500×1200 |

| T-slot (N×W×D) | mm | 3×18×100 | 3×18×100 | 5×18×100 | 5×18×100 |

| Tafiya | |||||

| X axis tafiya | mm | 640 | 640 | 850 | 1000 |

| Y axis tafiya | mm | 400 | 400 | 500 | 500 |

| Z axis tafiya | mm | 400 | 500 | 600 | 600 |

| Machining kewayon | |||||

| Nisa daga cibiyar spindle zuwa gaban shafi | mm | 440 | 476 | 572 | 572 |

| Nisa daga ƙarshen sandal zuwa teburin aiki | mm | 120-520 | 120-620 | 120-720 | 120-720 |

| Girman inji | |||||

| L×W×H | mm | 2200×2100×2500 | 2200×2100×2550 | 2540×2320×2780 | 3080×2320×2780 |

| Nauyin inji | |||||

| Max. ɗaukar nauyi na worktable | kg | 350 | 350 | 500 | 600 |

| Nauyin inji | kg | 3900 | 4100 | 5200 | 5600 |

| Spindle | |||||

| Ramin Spindle taper | BT40 | BT40 | BT40 | BT40 | |

| Ƙarfin spinal | kw | 5.5 | 5.5 | 7.5/11 | 7.5/11 |

| Max. saurin gudu | rpm | 8000/10000 | 8000/10000 | 8000/10000 | 8000/10000 |

| Ciyarwa (kai tsaye) | |||||

| Max. saurin ciyarwa | mm/min | 10000 | 12000 | 12000 | 12000 |

| Saurin ciyarwa (X/Y/Z) | m/min | 20/20/10 | 30/30/24 | 32/32/30 | 32/32/30 |

| Bakin ball (diamita + gubar) | |||||

| X axis ball dunƙule | 3210 | 3212 | 4016 | 4016 | |

| Y axis ball dunƙule | 3210 | 3212 | 4016 | 4016 | |

| Z axis ball dunƙule | 3210 | 4012 | 4016 | 4016 | |

| Mujallar Kayan aiki | |||||

| Ƙarfin mujallar kayan aiki | T | 16 | 16 | 24 | 24 |

| Lokacin canza kayan aiki | s | 2.5 | 2.5 | 2.5 | 2.5 |

| Daidaitaccen matsayi (Mizanin Ƙasa) | |||||

| Daidaitaccen matsayi (X/Y/Z) | mm | 0.008 | 0.008 | 0.008 | 0.008 |

| Daidaiton sake sanyawa (X/Y/Z) | mm | 0.005 | 0.005 | 0.005 | 0.005 |

| A'A. | Suna | Alamar |

| 1 | CNC tsarin | Seimens 808D SYSTEM |

| 2 | Babban motar | Cikakken saitin tuƙi na Siemens gami da motar servo |

| 3 | Motar axis X/Y/Z, direba | Seimens |

| 4 | Ƙwallon ƙafa | Hiwin ko PMI (Taiwan) |

| 5 | Ƙunƙarar ƙwallo | NSK (Japan) |

| 6 | Jagoran layi | Hiwin ko PMI (Taiwan) |

| 7 | Injin leda | POSA/ROYAL (Taiwan) |

| 8 | Mai musayar zafi | Taipin/Tongfei (Haɗin gwiwa) |

| 9 | Lubrication tsarin manyan abubuwa | Proton (Haɗin gwiwa) |

| 10 | Babban abubuwan tsarin pneumatic | AirTAC (Taiwan) |

| 11 | Babban kayan aikin lantarki | Schneider (Faransa) |

| 12 | Ruwan famfo | China |